The UVLED curing equipment has been continuously improved in the process of development, and now there is a curing equipment with good curing effect and very practical on the market. In the traditional curing mode, most of the light sources are provided by mercury lamp irradiation, and curing is performed at the same time, and this curing method will increase the temperature due to the long irradiation time, and the volume of the entire equipment will be relatively Large, expensive consumables, there will also be problems such as pollution of the environment.

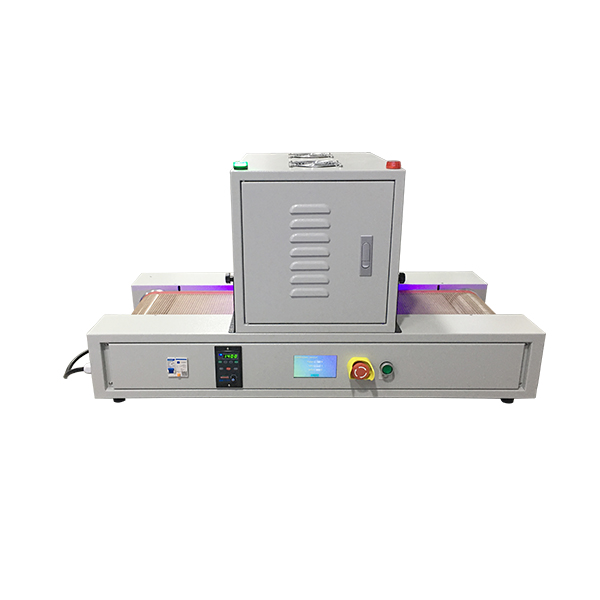

The current UVLED curing machine has a constant light intensity and a very good temperature control mode, which can realize portable shape or special curing equipment for assembly line or single-product curing box for experimental use according to customer needs. The upgrade from the appearance to the internal materials has greatly reduced the procurement cost, and in the process of use, due to the low energy consumption, less heat is generated, the scope of use is wider, and the maintenance cost is low.

After the product was launched, it has played a very helpful and promoting role in the whole industry from the improvement of quality to the performance of energy saving and loss. At present, the UVLED curing machine on the market is mainly used in the microelectronics industry PCB industry, medical equipment, optics, optical communication and other industries. Especially in the assembly line production process, fast curing can effectively improve the production efficiency.

Because it is a cold light source, products with high thermal sensitivity can also be cured in the UVLED curing machine, and because it is not irradiated by a mercury lamp, there is no generation of pollutants, so that the current UVLED curing machine has the characteristics of environmental protection. At the same time, it also reduces the energy consumption used, which provides more favorable help for the development of the enterprise.

As a manufacturer of UVLED curing equipment, Shenzhen Height-LED is committed to providing customers with a complete set of curing solutions. The products have standard products and can also customize products according to customer needs. If you have UVLED curing requirements, you can contact online customer service, or call for consultation and exchange.